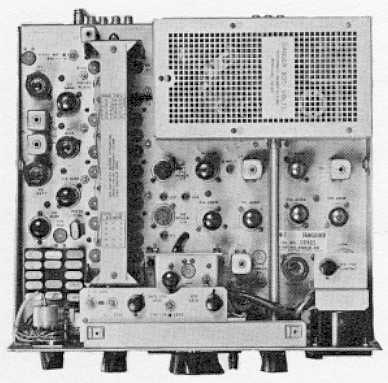

I was intrigued by a transceiver which was the backbone of voice and teletype communications throughout Laos. In its basic configuration, it put out some one hundred watts of power. Coupled with an amplifier, it was capable of putting out some five hundred watts. The KWM-2 was used extensively for teletype communications throughout Laos; however, none of our three radio technicians which consisted of US Army, US Air Force and a civilian Filipino had ever been trained to work on them. When a unit was defective, we simply put it in a Samsonite suitcase and shipped it to a US Air Force maintenance facility in Udorn, Thailand. I could not accept this arrangement and after a few weeks on the project, I called the air force maintenance facility in Udorn and asked to speak to whoever was repairing our KWM-2 transceivers. I spoke to an Air Force Tech Sergeant who managed the Radio Section. He became defensive and wanted to know who I was and why I was interested in the status of his repairs. I assured him I was totally satisfied by the repairs but only wanted to know if there were any trends he may be finding which we could possibly identify and repair ourselves in Project 404.

“What is Project 404,” he asked.

“Project 404 is a US military project involved in training and providing logistical assistance,” I replied. “The KWM-2’s which we send you to repair are our main means of communication for our project.”

He was getting too inquisitive, and I could not just brushoff his curiosity about our project because I needed his support. I asked him if I could come meet with him so we could spend a couple of hours discussing the KWM-2 problems he was finding. “I suppose we can do that,” he said, “but you’ll have to make arrangements with my commander.” He provided me his commander’s name and phone number.

Once I hung up, I went to see my supervisor, Rodney, who had been on the project for some three years. I explained to him that I had contacted the repair supervisor at the air force maintenance facility in Thailand, and I needed him to make the necessary arrangements for my visit there.

“But why do you want to upset the system that’s been working well for so long,” Rodney wanted to know. “We identify the defective radios, ship them to Thailand, they get fixed and we’re back in business. We don’t need to send anyone there!”

“Rodney , we have three trained radio technicians here,” I argued. “Only problem is that none of us ever trained on these KWM-2’s. We need a brief training session and all the repair manuals to start doing our own repairs here.”

Rodney was hesitant. He didn’t like to upset the system. Still, he presented my plan to our director who thought it would be a tremendous boost if we could repair our KWM-2’s in Laos. He arranged for me to meet with the air force commander in Udorn, Thailand, and receive one day’s training from air force repairmen. I booked myself on the first Air America to Udorn for that next morning and called the air force sergeant to expect me.

Our director had given me the commander’s building number, so I took a military taxi upon arriving at Udorn air base. The commander greeted me like a VIP. He was a Lieutenant Colonel and informed his first sergeant to get us some coffee. The first sergeant came back with coffee and doughnuts. Neither of them had even a clue that I was only an enlisted man in civilian clothes! The commander asked for identification to verify that I was representing Project 404. I handed him my US Embassy ID card. He was satisfied with that and now wanted to know more about the project. “I understand that you folks operate primarily in Laos, but what do you guys do there?” he wanted to know. He asked a few other questions before he realized that I was not going to provide any real answers. I kept giving him my director’s number and told him that our director was much more qualified to answer his questions. At this point, he got up saying, “Well, that’s enough chit-chat. Let me walk you over to the radio section.”

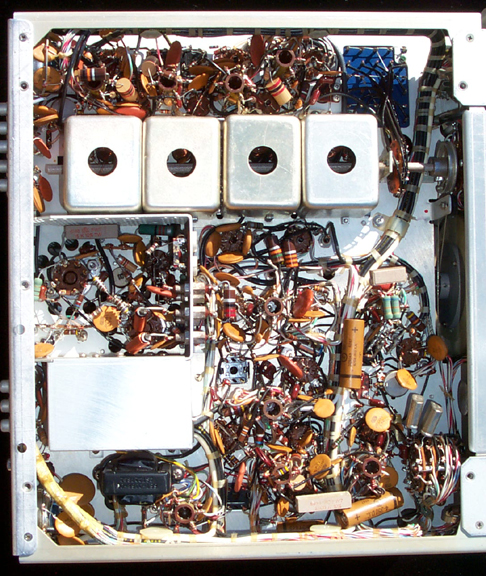

He introduced me to the Tech Sergeant whom I had talked with just a few days earlier. He had pulled all the work orders for the previous ninety days and spent the first hour showing me how realignment often fixed the majority of problems. The KWM-2 was tube designed, so any tube replaced required realignment of associated circuitry. Only a handful of them had actual electronic component failures. He provided me alignment procedures and several other troubleshooting guides and complete manufacturer repair manuals.

I shared my new knowledge with the other two technicians and requisitioned additional repair manuals to facilitate in-shop repairs. Since the Filipino civilian technician was forbidden from travel to remote sites, he became the primary technician for our massive number of KWM-2 transceivers. We had finally severed our dependency on the US Air Force technical support in Thailand.

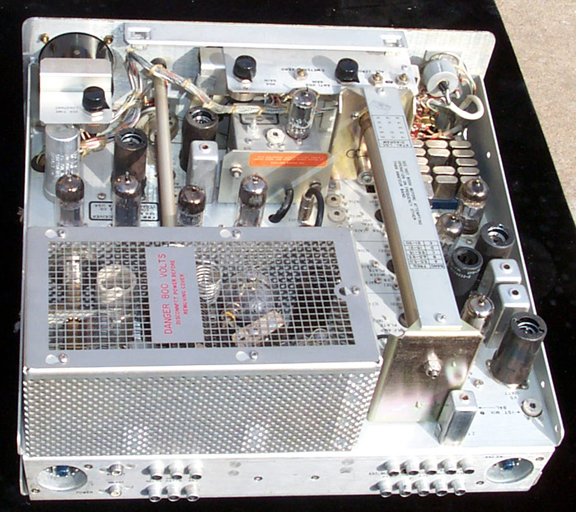

KWM-2 Transceiver Top

©Copyright texan@atudemi.com - January 2022